Electrolab Model 2100 Digital Level Sensor Ideal for Separators

Electrolab’s sales team receives many calls from operators who are unhappy with the current level measurement technology in their separators. Many technologies struggle finding the interface level in the separator environment. Surface fouling, contaminants, tank flow rates and other environmental conditions add to the challenge. Electrolab’s Model 2100 Digital Level Sensor (DLS) works extremely well in this environment. Consider the Model 2100 DLS for level measurement when process conditions allow.

Operating a separator is all about controlling the interface. The purpose of the separator is to recover oil, dispose of water, and remove gasses. A level sensor must find and measure the interface reliably to control the performance of the separator. Electrolab’s Model 2100 DLS measures the oil/water interface directly, regardless of the thickness of the emulsion layer. This allows for reliable control of the water level and efficient removal of the water. The accurate measurement of total fluid and water interface leads to accurate and reliable results in the separation process. And, unlike with Guided-Wave Radar (GWR), there are no false echoes.

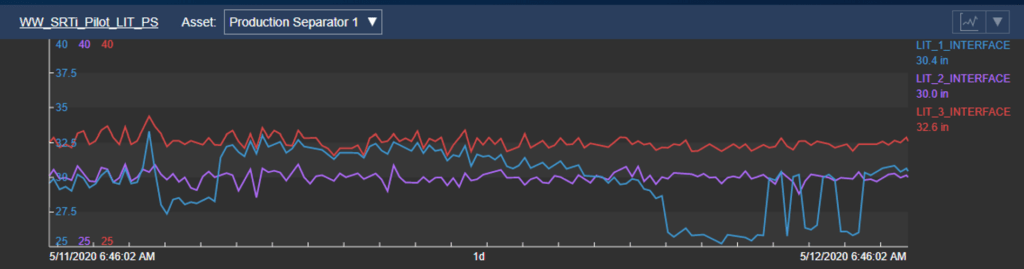

Let’s review a recent run with an end user shown in the graph below. The red line shows measurements by the Model 2100 DLS. The blue line shows measurements by a competitive guided wave radar sensor in the same separator vessel. (The purple line is a guided wave radar in the bridle of the vessel, not exposed to changing internal conditions.) Notice how the guided wave radar’s measurements show much wilder disruptions and take longer to recover. Also notice how the GWR chases a false disruption and takes an extended time to recover. Note that the DLS measurement is steady and accurate.

Many sensors in separators are subject to fouling from paraffin and scale. The paraffin falls out of solution as the separator loses temperature and pressure. Electrolab treats all stainless steel DLS level sensors with e9 Pro Performance Treatments as. This patented surface treatment slows build up, preventing false measurements and premature failures.

A separator offers a very harsh environment, with a great deal of flow and splashing. This environment leads to false measurements. Metal parts wear from the exposure and this wear can interfere with some level sensor measurement technologies, leading technicians to tune out signals and chase false readings. Electrolab’s Model 2100 DLS resides in the fluid where it obtains a direct measurement, not effected by splashing, foam, condensate, or any of the other environmental factors frequently found in separators.

In summary, the separator is a very difficult place for measurement. Operators require a sturdy, reliable, and accurate solution for this harsh environment. Electrolab designed the Model 2100 Digital Level Sensor for such an environment and we have the data and experience to prove it!

Sorry, the comment form is closed at this time.