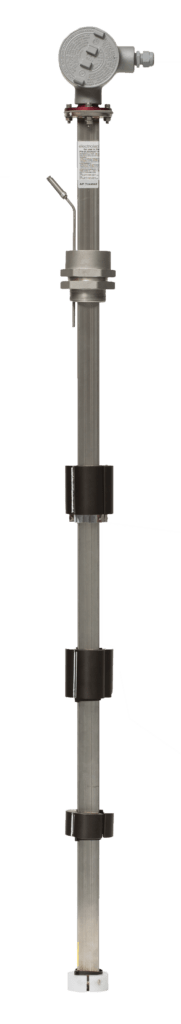

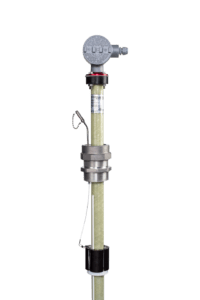

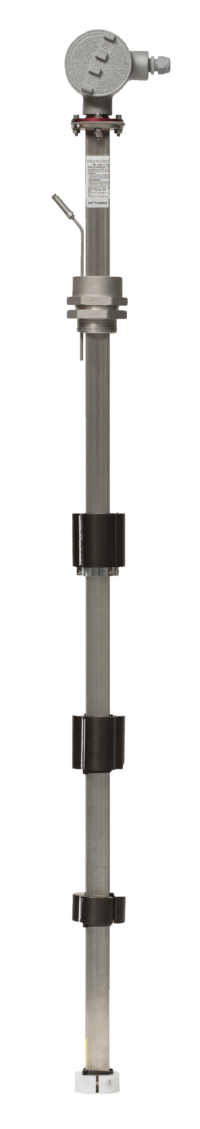

High-Level Shut-In is available for all Model 2100 Digital Level Sensors (DLS). Stainless Steel, Fiberglass and RU Flex sensors offer this option.

With the addition of a third float, the Model 2100 DLS with High-Level Shut-In provides two digital outputs: one for a high-level alarm, and one for a high-level shut-in. This is all accomplished with two distinct circuits: one for normal continuous level and temperature measurement, and the other for high-level alarm shut-in.